Blind rivets

GESIPA® blind rivets come in a wide range of forms, materials, shapes, lengths and even colours. Depending on the application you have in mind for the GESIPA® blind rivet, you can choose to order a standard blind rivet for delivery straight from the GESIPA® warehouse or bespoke blind rivet designed especially for your application. Thanks to the perfectly coordinated shapes and premium materials of the individual components, GESIPA® blind rivets guarantee a high-quality, neat connection that

looks good every time. GESIPA® blind rivet technology has come to be an essential part of many modern industrial production processes requiring joining technology owing to its high levels of cost-effectiveness and versatility. It combines a number of advantages in one solution, providing access to the blind side in an application, reliably joining a wide range of materials with lasting effect, including more sensitive ones, and documenting the setting process where required.

Any questions?

Which may be the best rivet for your application? Do not hesitate to contact us -we will be happy to advise you!

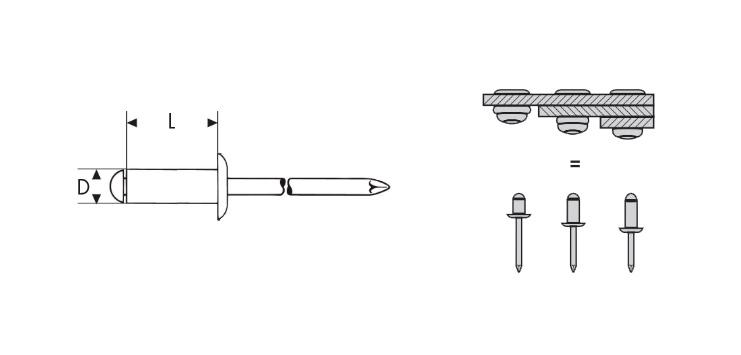

GESIPA® blind rivets – terminology

The blind rivet consists of two parts: the rivet body (1) and the mandrel (2). The rivet body consists of the setting head (3) and the shaft (4). The setting head is found on the processing side and is variable in diameter and shape. There are dome, countersunk and large flange versions. The rivet body is available in different lengths depending on the material thickness to be riveted. The rivet mandrel is used to deform the rivet body. It contains the predetermined breaking point (5) This is where the rivet mandrel breaks after the rivet has deformed. The mandrel head (6) is the remaining part of the rivet mandrel in the rivet body. The residual mandrel (7) is the part of the rivet mandrel that is disposed of from the set rivet via the blind rivet setting tool.

GESIPA® blind rivets – lasting connections

During the setting process, the mandrel body is moved using the setting tool jaws, deforming the hollow rivet until it is firmly positioned in the component as predefined. In the end, the mandrel body breaks off at the specified point (the predetermined breaking point) and can be disposed of via the recycling system. The rest mandrel is the spent mandrel left behind in the hollow rivet and can provide an additional locking function depending on the application in question.

Find the right blind rivet

You can buy our blind rivets from selected specialist retail partners. Are you an industrial manufacturing company and process large quantities of blind rivets? Simply get in touch with us. We will help you select the right blind rivet for your application.

contaCt

What material are rivets made of?

Blind rivets from GESIPA® are available in different materials. The right combination of materials can be selected depending on the application.

Aluminium/steel: The hollow rivet is made of an aluminium alloy, the mandrel of galvanised steel

Aluminium/stainless steel: The hollow rivet is made of an aluminium alloy, the mandrel is made of A2 stainless steel

Aluminium/aluminium: The hollow rivet and mandrel are made of an aluminium alloy

Steel/steel: The hollow rivet and mandrel are made of galvanised steel

Copper/steel: The hollow rivet is made of copper, the mandrel of galvanised steel

A2 stainless steel: The hollow rivet and mandrel are made of A2 stainless steel

A4 stainless steel: The hollow rivet and mandrel are made of A4 stainless steel

Stinox: The hollow rivet is made of A2 stainless steel, the mandrel is made of galvanised steel

What head shapes are available for blind rivets?

Blind rivets are not only available in different materials and sizes, but are also differentiated according to their head shape. The three different head shapes - dome head, countersunk head and large flange- should be selected according to the application to be riveted in order to ensure optimum performance and reliability. The dome head is the most common type of blind rivet. The dome head rivet is well suited for fastening thin and/or easily deformable materials. In addition, the dome head of blind rivets provides a good contact surface on the materials to be riveted and ensures a good hold. The countersunk head, on the other hand, is used for blind rivets where, for example, a smooth surface is required after the setting process or the riveted element comes into contact with other components afterwards and the rivet must not interfere with this. Compared to the dome head, the countersunk head is conical in shape and protrudes less from the connected application than a dome head. Last but not least, blind rivets also have a large flange shape. As the name suggests, the large flange rivet has a larger contact surface on the material after the setting process. This is particularly suitable for sensitive materials or when the joint has to withstand a high load.

What else you should know about blind rivets

Questions and answers on the subject of blind rivets.

Blind rivets, also known as "pop rivets", are used in a wide variety of industries. They are used more often than you might think, because rivets are particularly practical when you only have access to the workpiece on one side, which is why they can be set quickly and easily. Blind rivets are generally used in general metalworking. Rivets are suitable for use wherever thin sheets or different materials need to be joined where conventional screw connections are impractical. They can be found in the automotive industry, for example, where the fasteners are often used to attach panelling or bumpers to the vehicle. Blind rivets are used in the general construction industry for façade construction or to fasten panels and roof profiles. The list is long, because blind rivets can also be used in the truck and trailer sector, in electronic applications or in the white goods sector.

The choice of the right blind rivet depends on various factors. Firstly, the application itself must be considered and what special requirements are placed on the blind rivet used. Not only does the size of the rivet play a role, but above all the material must be selected to suit the materials that are being joined together. Steel blind rivets are widely used, e.g. for joining heavy-duty components. They are usually found in applications where high tensile strength is required. Stainless steel rivets, on the other hand, are often found in areas where corrosion is a problem, as they are rust-resistant. Aluminium blind rivets are usually found in the automotive or aviation sectors in particular, as weight is very important in these industries and aluminium rivets are extremely light. But there are not only metal blind rivets - plastic blind rivets are often used to join plastic parts, as they are corrosion-free and only require minimal tightening values. Due to their electrical conductivity, copper blind rivets are often used in electrical applications. There are also rivets that consist of two materials and are therefore particularly versatile. Many other factors determine which blind rivet is best suited to which application. GESIPA supplies a wide range of the above-mentioned blind rivet types for every area of application.

Pop rivet is another term for blind rivet. Pop rivets are used to join two or more materials. Pop rivets are often used on components that are difficult to access, where access is only possible from one side. A pop rivet or blind rivet consists of two parts: The hollow rivet and the rivet mandrel. These fasteners are processed with a special riveting tool, which deforms the rivet head by pulling on the mandrel. The remaining rivet mandrel then breaks off, creating a clean rivet joint. Pop or blind rivets are available in a wide variety of designs and for different applications. For example, the GESIPA® CAP® blind rivets are airtight and watertight and the eFast PolyGrip switch cabinet rivets are electrically insulating.

There are different types of rivets in blind rivet technology.

Dome head blind rivets: The dome head rivet ensures a large contact surface and therefore a good hold of the rivet on the material. It is the classic blind rivet.

Countersunk blind rivets: The rivet head is countersunk. This enables a more attractive surface aesthetic and prevents injuries caused by protruding rivet heads.

Large flange blind rivets: With these blind rivets, the rivet head is relatively large compared to the rivet shank. This enables a larger contact surface, which can be an advantage in certain applications to ensure better load distribution or increased stability.

Multi-range blind rivets: With one dimension, a GESIPA® PolyGrip® blind rivet can replace up to five different dimensions of DIN standard blind rivets. The clamping range is therefore significantly larger and enables a wide range of applications with just one dimension.

Peel blind rivets: Peel blind rivets are press-fit blind rivets that are ideal for soft or porous components such as wood, fibreglass, hard fibre or plasterboard. During the setting process, the rivet mandrel falls out of the hollow rivet and the rivet mandrel divides the hollow rivet into four parts on the closing head side. These parts then bite into the material.

Magazine blind rivets: The blind rivets are mounted on a special rivet mandrel and are ready for immediate use. When a rivet is set, the next one moves in immediately so that the blind rivets can be processed quickly and without dropping or reloading.

Plastic rivets: As the name suggests, these blind rivets are made of plastic and are therefore electrically non-conductive, corrosion-free and particularly gentle on painted surfaces. They are mainly used when joining plastic parts or when only low tightening values are required.

There are also

Blind rivet nuts: These are fasteners that can be used to create a heavy-duty thread in thin materials, even if they are only accessible from one side.

Blind rivet studs: As a combination of blind rivet nut and screw, blind rivet studs are a technical and economical alternative to weld studs or other multi-part T-slot systems

Choosing the right length of blind rivet depends entirely on the application and the material to be riveted. The clamping range describes a range of the minimum and maximum material thickness that can be processed with a specific rivet shank length. If a longer rivet is selected, a greater material thickness can be crimped than with a shorter rivet shank length.

However, this rule of thumb makes it very easy to determine the correct length:

Material thickness (for several materials, the material thicknesses are added together) + rivet shank diameter (D) = rivet shank length (L)

An example:

Material: sheet metal 3 mm + sheet metal 3 mm + hole 4 mm = 10 mm rivet shank length

= This results in a blind rivet with the dimensions: 4 x 10

Why do this type of rivet appear to be "blind"?

Technically speaking, the blind rivet consists of two components, the hollow rivet and the rivet mandrel. Whereas with other joining techniques, such as screwing, clinching and self-pierce riveting, the component must always be accessible from both sides, what is really special about the blind rivet is that only one side of the component needs to be accessible. Blind riveting is therefore a process in which the rivet holds two or more materials together by pressing them together. The back of the component does not have to be sealed in a second work step, but is automatically sealed by the technical design of the blind rivet.

Further blind riveting products

Perfect processing tools and joining elements for every application